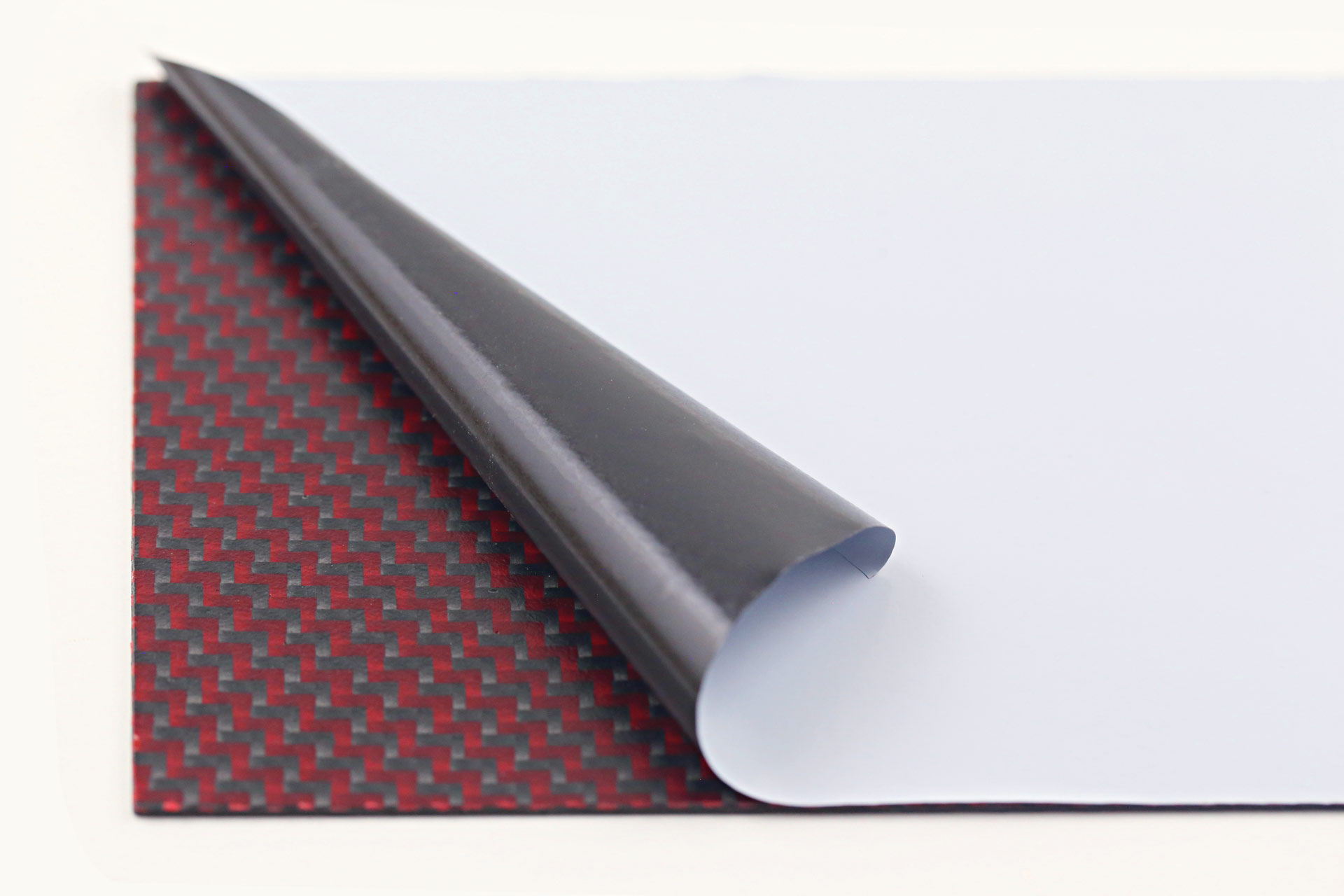

Plastic Protection

Samples for your application

Request a quote or free sample

Call us

888.753.3037

Plastic Surfaces

Plastics are everywhere! From large-scale flat sheet stock to molded containers, appliances and electronic devices, plastic has been there, done that. But to keep plastic surfaces safe, from the factory floor to the customer’s hands, careful handling is needed. Scratches, industrial solvents, painting mishaps and assorted contaminants can damage the finish, driving up costs and devaluing the product.

Hazards arise during:

|

|

Whether you’re dealing with polycarbonates, acrylics or polyesters, Surface Armor offers a range of custom-designed plastic protective films to meet your needs. Plastic protective films are available in the exact dimensions you require to cover everything from home electronics or office equipment.

Types of Plastic Protection Films

Adhesive Type

This is the product identification number of the adhesive used to attach the protective film to the plastic surface.

Tack

Measured in ounces per lateral inch, this defines the level of “stickiness” of a particular adhesive. Because there are many variables at play, the tack level of most adhesives will be expressed as a range of values rather than a single, specific measurement.

Film/Paper

This indicates the type of plastic or paper that the film is made of.

Why Surface Armor

Custom to You

The right film, adhesive, width, length, and perforation that fits. your exact needs

Quick Ship

Most orders ship within

2 days

Just in Time Quantities

You won’t need to order a lifetime supply.

1,200 sq ft order minimums

Get FREE Samples Today

Contact us now and we will ship you a free sample to test

Learn more about our process

Since 2005, Surface Armor has been proud to provide custom temporary surface protection product solutions that protect the products of customers in numerous industries. Don’t put your product at risk by shipping it without Surface Armor protective film! Contact us today.