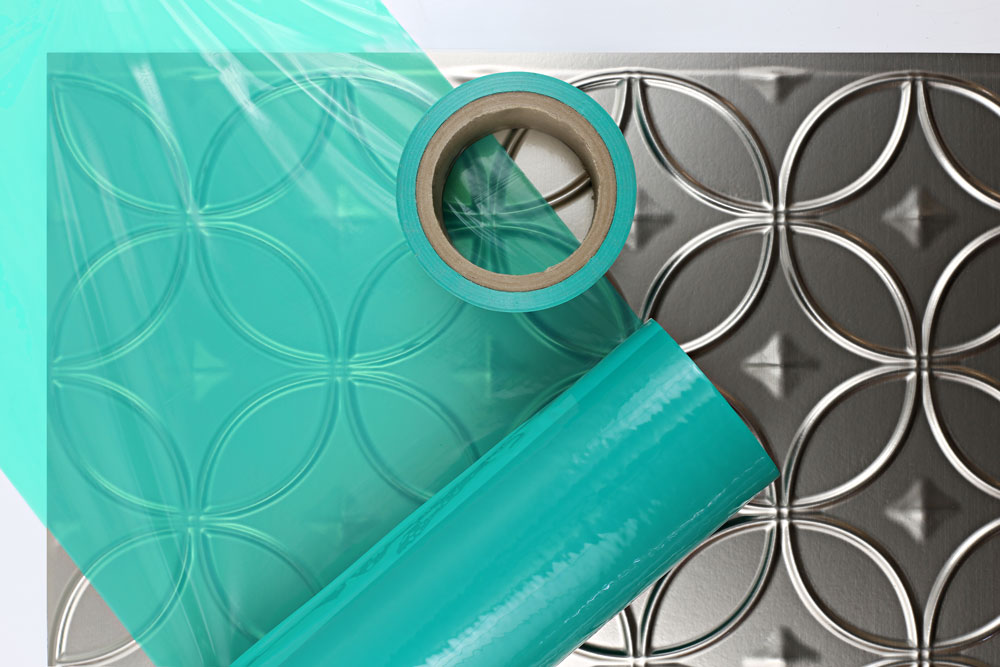

Metal Surface Films

Samples for your application

Request a quote or free sample

Call us

888.753.3037

Metal Surfaces

Metallic surfaces are not immune to damage and wear, especially during the fabrication and finishing processes. Metal surfaces can be marred by chatter marks, scratches or swirls, or contaminated by overspray, solvents, dust and the like. Potential hazards to your metal surfaces arise during:

|

|

Damage to the metal surface at any step can be costly, putting pressure on both your timeline and your bottom line. You can prevent any such damage from occurring with Surface Armor metal protection film. Our protective films provide a temporary barrier that can absorb scratches or scrapes and block any liquid or solid contaminants. The thin, disposable film can then be quickly peeled off upon delivery to the next stage of manufacturing, or to the end customers themselves. We carry Protective Films to cover almost any type of Uncoated or Powder Coated Metal even Kynar-Duranar finishes, all delivered to you in the size and shape that will best suit your needs. Protect your Metal Extrusions, Architectural Framing Systems or Metal Building Panels with our 365 Day UV Rated Low Tack High Performance Protective Films.

Protective Film Traits

Adhesive Type

This is the product identification number of the adhesive. Smooth surfaces typically require light adhesive while textured surfaces usually thicker and more robust adhesive characteristics. Why? If the adhesive is just contacting the “peaks” of the surface, it may be touching less than 5% of the total surface area and be prone to falling off the surface.

Tack

Measured in ounces per lateral inch, this defines the level of “stickiness” of a particular adhesive. Because there are many variables at play, the tack level of most adhesives will be expressed as a range of values rather than a single, specific measurement.

Material

Material – This identifies the product substrate, itself (type of plastic / paper).

Our Customer Success representatives will help you select the ideal Surface Armor products for your application. With numerous variables affecting the interaction between protective film and surfaces, it’s best to test multiple samples across all phases of the intended protection life cycle.

Why Surface Armor

Custom to You

The right film, adhesive, width, length, and perforation that fits. your exact needs

Quick Ship

Most orders ship within

2 days

Just in Time Quantities

You won’t need to order a lifetime supply.

1,200 sq ft order minimums

Get FREE Samples Today

Contact us now and we will ship you a free sample to test

Learn more about our process

Since 2005, Surface Armor has been proud to provide custom temporary surface protection product solutions that protect the products of customers in numerous industries. Don’t put your product at risk by shipping it without Surface Armor protective film! Contact us today.